Equipment

Application

Signal diagnostics

Signal diagnostics

350 MHz digital oscilloscopes (Rigol/Keysight), 3 GHz spectrum analyzer

Bus, RF, and clock signal testing

Electrical measurements

Electrical measurements

6.5-digit multimeters, ESR meters, micro-ohm meters < 1 µΩ

Precise measurements of components and tracks

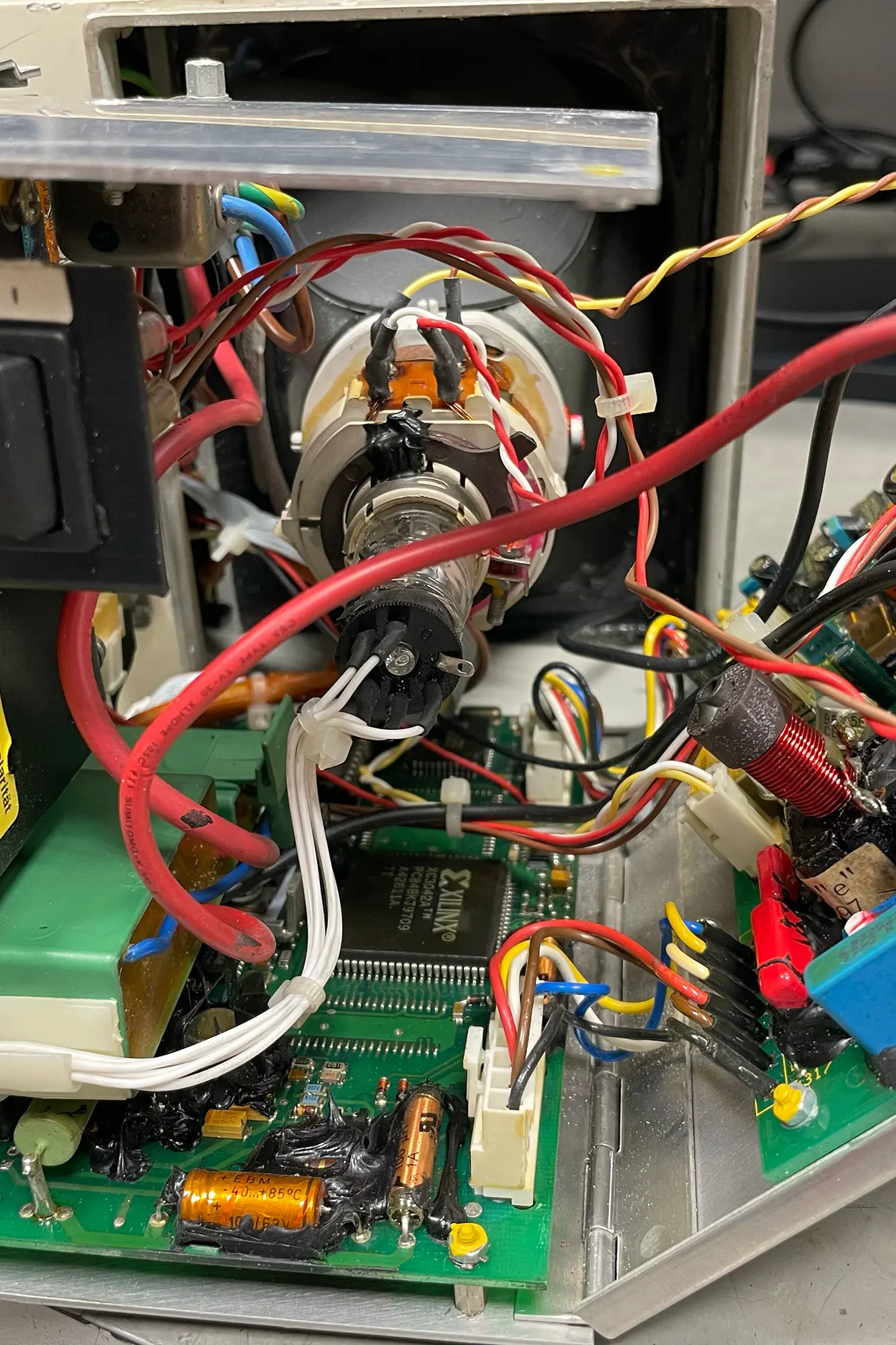

Rework & soldering

Rework & soldering

JBC and Hakko stations, 1000 W hot air, YH-853A IR heater, lead-free solders

BGA/QFN replacement, reballing, micro-soldering

Optical inspection

Optical inspection

10-90× trinocular microscopes with 4K camera, AOI, HD PCB endoscope

Quality control of solder joints, tracks, and connectors

Thermography

Thermography

Fluke TiX580 camera, IR pyrometer

Hot spot detection, thermal analysis

Programming & testing

Programming & testing

Over 20 types of programmers, including TL866II, JTAG/SWD, Boundary-Scan, in-circuit emulator

Flashing, debugging, functional testing

Power analysis

Power analysis

0-60 V / 10 A power supplies, 300 W electronic load

Load testing, PSU characteristics

X-ray inspection

X-ray inspection

RTG BGA VJ Electronix XQuik II

Evaluation of CSP/BGA connections